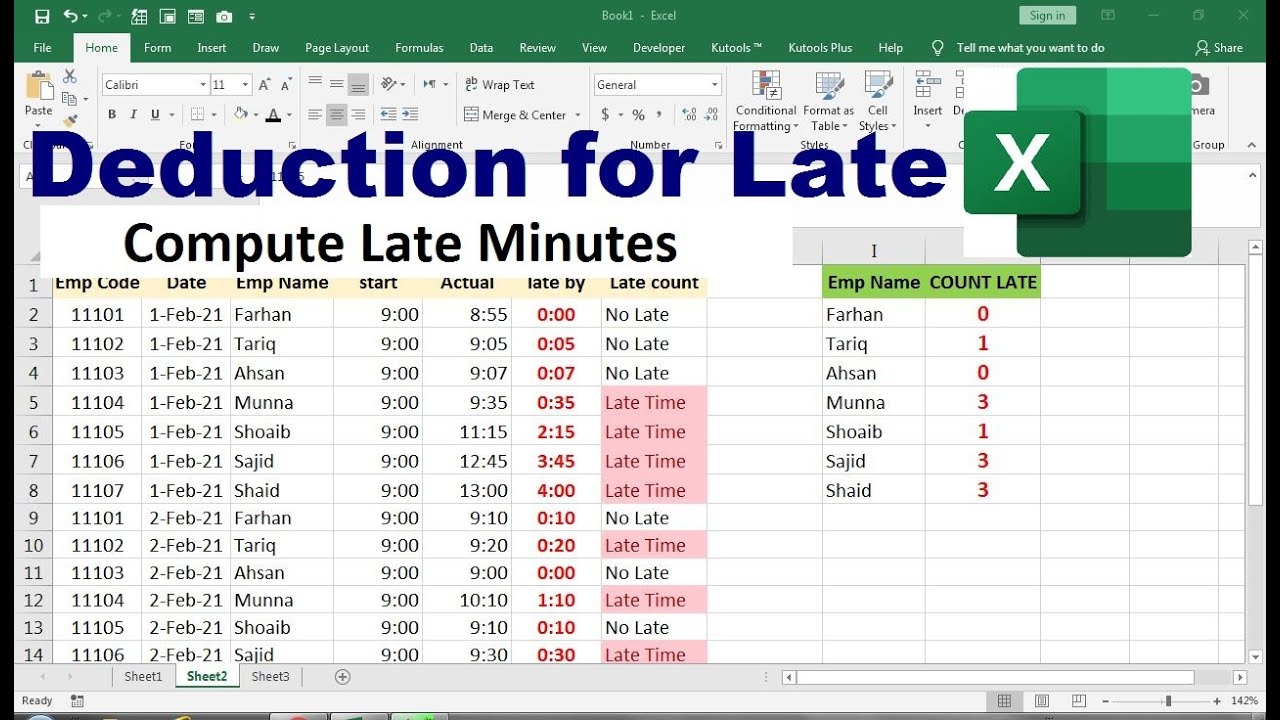

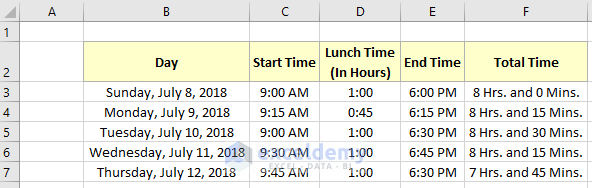

So hourly production rate from this operation will be 3 times the single operator’s output.Apart from tracking work hours, an Excel timesheet template comes in handy while generating employee payroll based on billable hours. In case, you have assigned more than one machine for a single operation, and you know the operator’s average efficiency, then you can estimate total production in that specific operation.Įxample: Let’s say on the shirt bottom operation, you have assigned 3 machines and 3 operators. Formula used -Įstimated Production/Hour = (No. It may be different for few operations than calculated production per hour as you set machine numbers to round up value. Calculate estimated production per hour (with multiple workstations) It is calculated according to the machine assigned to each operation. Images: Production per hour calculation templateĢ. Production per hour = (60/0.75) x 80%= 64 pieces of garments His performance rate (efficiency) is 80%.

Let’s say Satish is working on an operation of a standard time of 0.75 minutes.

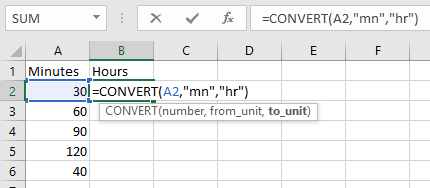

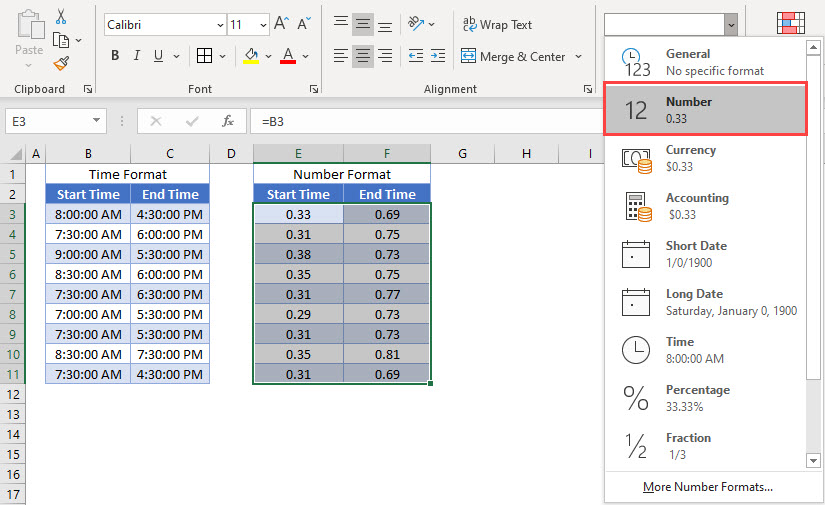

In the post, I will be showing you how you can calculate the estimated production per hour of a line in an Excel sheet. In the manufacturing sectors whatever items you are making, often you need to estimated hourly production and sometimes you may need to convert total production volume done by an employee (or workstation) into production per hour. Calculation of hourly production is required for many purposes.

0 kommentar(er)

0 kommentar(er)